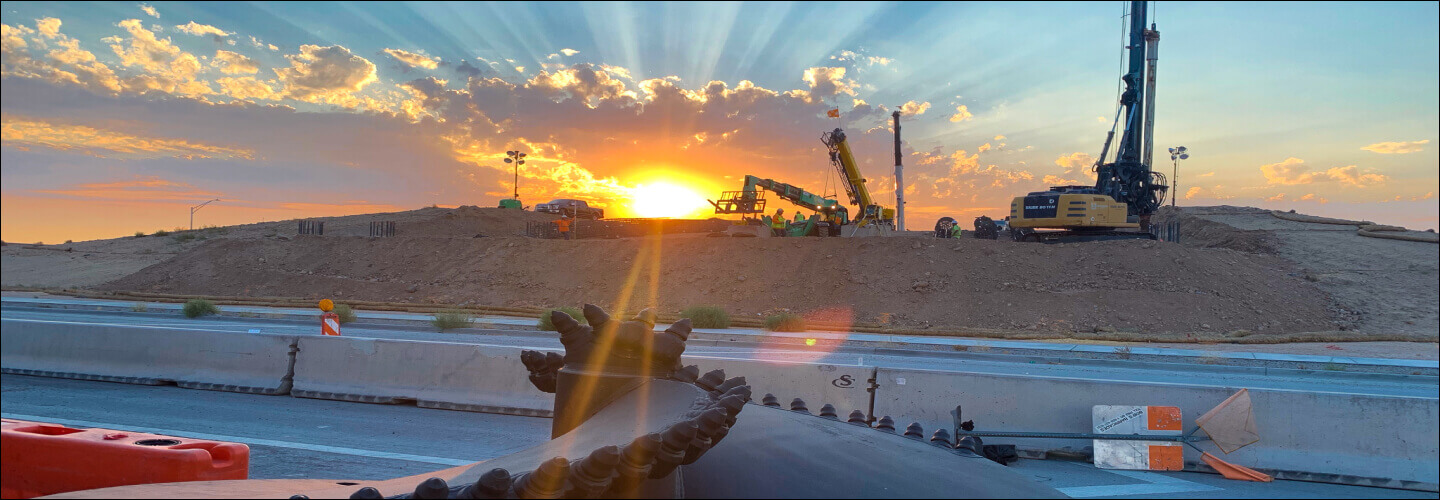

Building your vision on secure foundations

Leveraging experience and prioritizing safety, Buesing is more than the specialty contractor and employer of choice - we’re Simply the Best.

Civil Engineering Contracting — B.E.S.T.

Buesing Engineered Service Tradition : Empowered by our comprehensive scope of civil engineering solutions and over 55 years of experience, your vision is safe with Buesing. From concept to completion, our skilled professionals will deliver your project on time and on budget.

Landscapes We've Changed

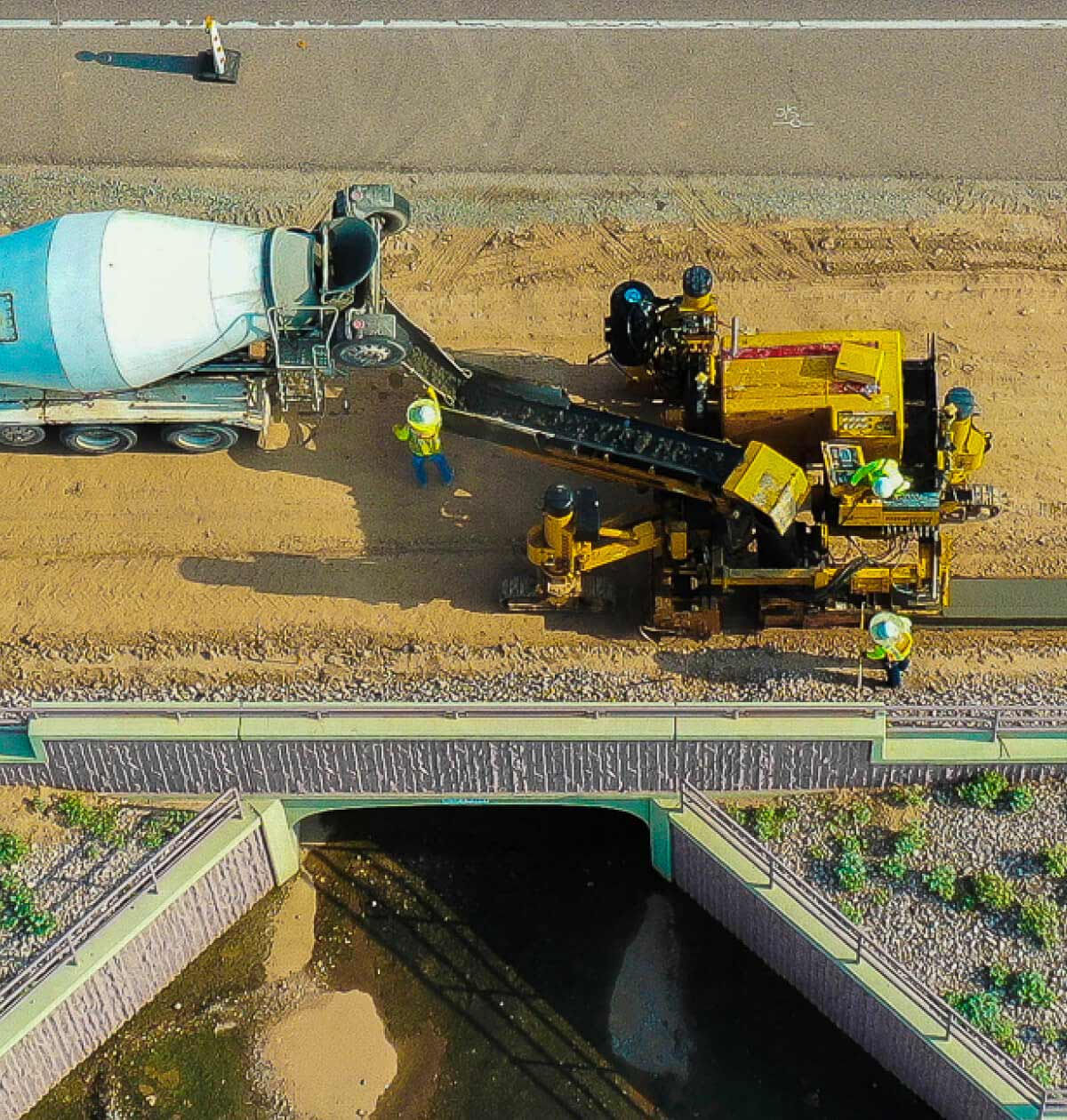

General Civil Engineering & Specialty Contracting Services — We Do It All.

Construction Veterans

Empowered by our comprehensive scope of civil engineering solutions and over 55 years of experience, your vision is safe with Buesing. From conception to completion, our skilled professionals will bring your project to life on time and in sync.

Cross Functional Synergy

Aligning the efforts of multiple subcontractors is not only time consuming, it's a hassle. Our professionals across functions collaborate effectively and efficiently because we’re not just colleagues - we’re a team.

Safety Culture

Safety at Buesing is the premise of everything we do. From the way we equip and train our employees to the priorities we set when designing and executing a project, Safety is a nonnegotiable principle in the Buesing culture.

Reliable & Punctual

Partnering with Buesing provides our customers with peace of mind. To achieve this, we make sure that your vision will be executed to a T and delivered on time.